Benefits of Wire Rope Isolators

Temperature Range

The temperature range of cable isolators is –300 to 500 degrees F. For elastomers, the useful range is typically –40 to 180 degrees F. Even in this range, however, the performance characteristics of elastomers can vary.

environmental resistance

Substances and chemicals such as ozone, oils, organic solvents, fuels, salt spray, and NBC decontaminant that can degrade elastomers, have no negative impact on cables.

outgassing

Even the most stable elastomers will outgas, degrade, and flake over time. Wire isolators are commonly used in space applications and in clean rooms, where outgassing of elastomers can cause serious problems.

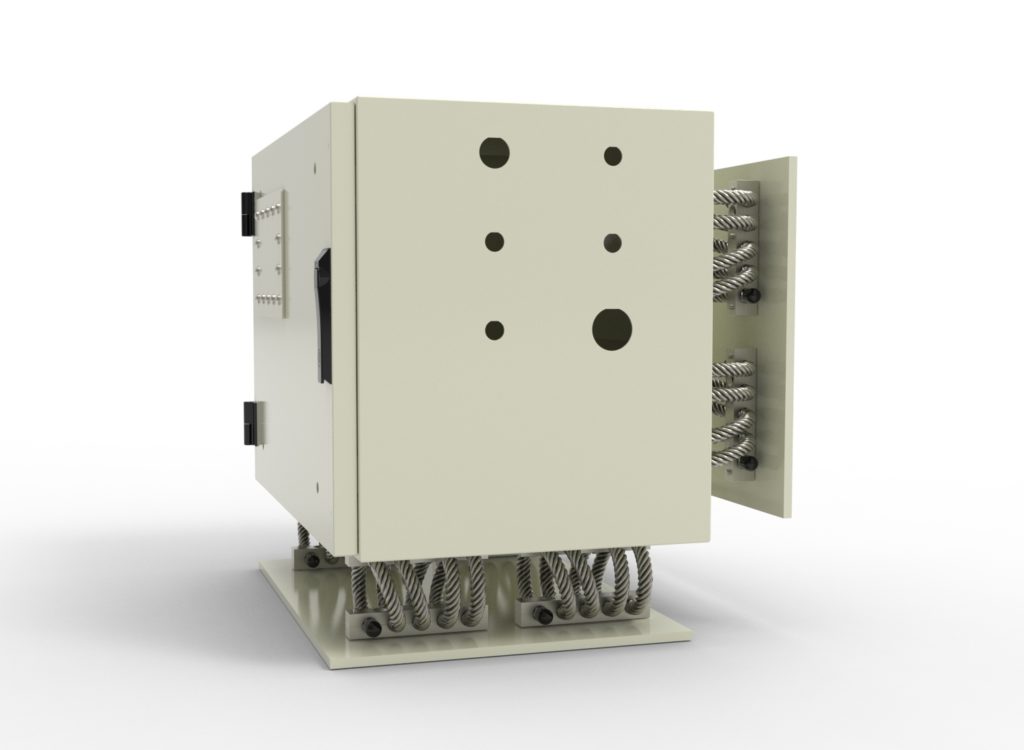

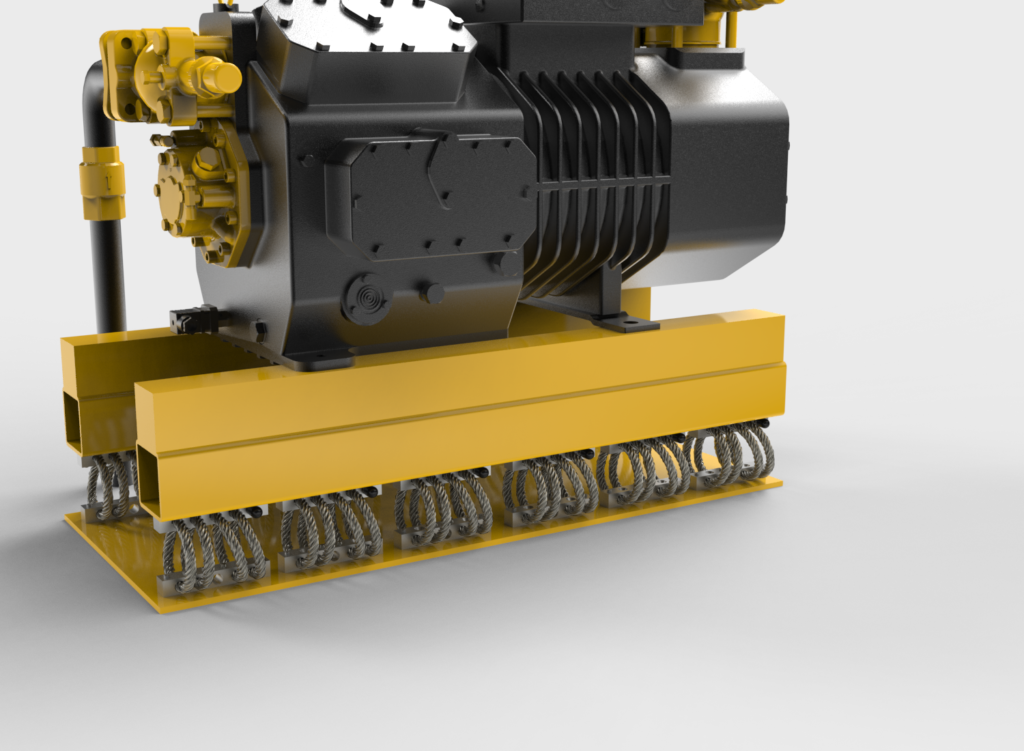

multi-axis capability

Cable isolators are a true multi-axis mount, which allows them to be installed in almost any geometry.

maintenance free

Cable isolators are an install and forget product. There is no need to service or replace components.

long life & reliability

A wire isolator will generally outlast the equipment they were designed to protect.

Compact design

The stroke efficiency of a mount is defined as the ratio of maximum displacement capability to isolator height. For cables, this ratio is ~.5, and can be as high as .75, making them among the most efficient mounts available.

customization

Wire rope isolators are the easiest and most cost effective isolators to customize. By simply varying the number of cable loops, height, cable diameter, etc…, the performance can be fine tuned to exact specifications.

low natural frequency

Isolation system frequencies as low as 3 Hz can be achieved with a properly balanced system.

high-damping

As the mount deflects, the tiny individual strands of wire rub together and dissipate vibrational and shock energy. The result is a damping constant (C/Cc) of ~20% (higher than any elastomer).

fail-safe

Even under conditions of extreme overload, cables will act to restrain equipment and prevent it from dislodging and becoming airborne.

cost-effective

Long life, low maintenance, and relatively low initial cost, makes cables the most cost-effective isolator on the market.